USE CASE

DTI

Digital Temperature Indicator

In an era where precision and efficiency are paramount, the DTI offers a revolutionary solution for temperature monitoring. This innovative product combines the simplicity of visual inspection with the power of digital data. Users can instantly check temperatures with the naked eye, while also accessing detailed digital information through modern connectivity tools like RFID, NFC, and QR code. This dual functionality ensures that you can monitor critical equipment both quickly and with high accuracy. The DTI is designed for easy installation and remarkable versatility, making it perfectly fit for a wide range of applications.

Versatile Applications

The DTI is designed for a wide array of applications across different industries, providing a simple yet powerful way to track thermal data and prevent potential issues. Here are a few examples of how they can be used:

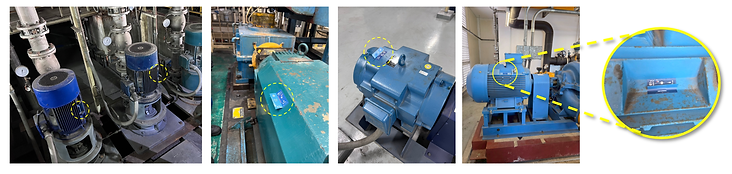

Manufacturing & Industrial Equipment

Motors and Servomotors: Monitor the operating temperature of industrial motors and servomotors to prevent overheating, which can lead to costly downtime and equipment failure.

Bearings: Detect heat in bearings early to prevent catastrophic machinery failure.

Welding Systems: Ensure the safety and quality of welding processes by monitoring the temperature of the equipment.

Hard-to-Reach Areas: Enable safe temperature monitoring from a distance in confined or dangerous spaces.

Electrical & Power Systems

MDB and Transformers: Monitor the temperature of MDBs and transformers to prevent fires and power outages.

HV Cable Lugs: Identify and address overheating in high-voltage cable lugs caused by loose or faulty connections.

Renewable Energy & Automotive

Solar Cells: Track the temperature of the connectors to identify potential hot spots that could damage the cells.

EV Chargers and batteries: Use the DTI to monitor the temperature of electric vehicle charging stations, ensuring they remain within safe operating limits during the charging process.

IT & Data Centers

Data Centers: Track the temperature on individual servers or power supply units to prevent equipment damage and ensure system uptime.

By providing a simple yet powerful way to track thermal data, the DTI helps businesses prevent equipment failure, optimize performance, and enhance overall safety. It is not just a product; it is a proactive tool for smarter and more reliable operations.